In the manufacturing industry, the term Industry 4.0 currently the symbol for the further development of industrial production. The vision describes a type of production in which everything is networked in the best possible way. Networking then enables self-controlling and self-optimising production (see also "What is Industry 4.0?”). But what is the historical course that led to Industry 4.0?

Evolution towards Industry 4.0

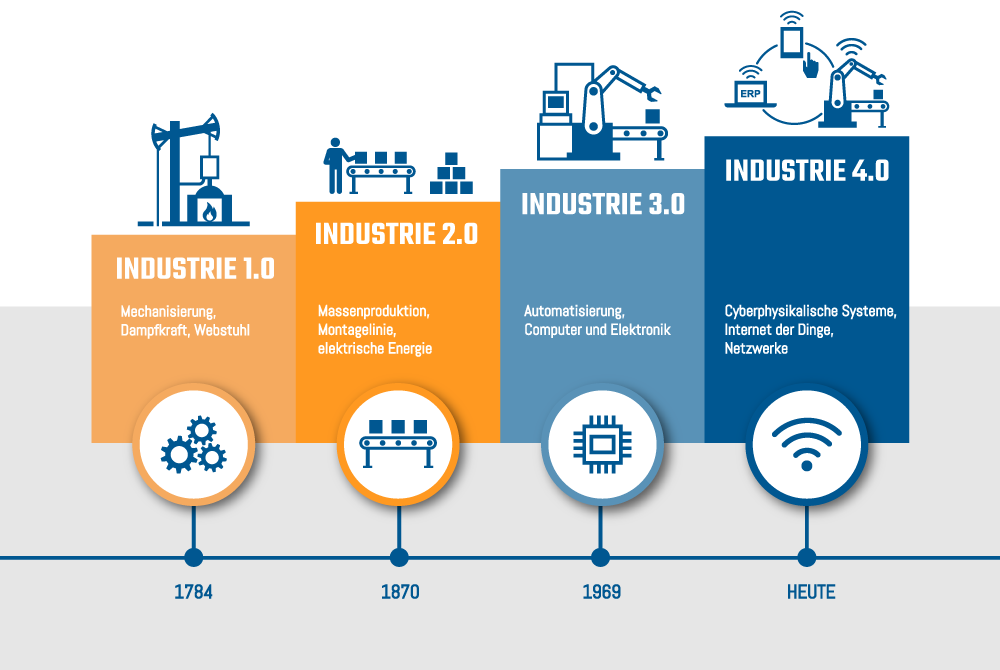

The designation of the different types of industrial production is of course not an active determination of the past, but a simplified categorisation made in retrospect of development. The different stages are not sharply delineated and yet each represents a kind of revolution in industry. This development up to the milestone Industry 4.0 is reflected in the further development and impact on society.Industry 1.0

Steam and water as a source of power

The first industrial revolution began at the end of the 18th century. Generally this is also referred to as the "Industrialisation" referred to. During this time, the first machines were powered by steam and water instead of human labour, e.g. power looms. New jobs were created in factories. Socially, this had far-reaching effects, because the world of work changed greatly. Workers were drawn away from agriculture and handicrafts to the factory floors, where they could expect higher wages on the one hand, but had to live with significantly worse working conditions on the other. In the countryside, on the other hand, the negative consequences were noticeable; businesses had to close due to a lack of workers. Due to these strong upheavals, the period is called the first industrial revolution.Industry 2.0

Assembly line and electricity

The next big step in development was electricity, motors and the invention of assembly line work. Electricity and motors made people independent of water and steam to drive the machines and thus much more flexible. The invention of the assembly line in car production by Henry Ford then ensured a significant increase in production efficiency at the beginning of the 20th century. Series production meant that products were manufactured in an even shorter time and in even larger quantities. It was the beginning of mass production. Much broader sections of the population were now able to buy products from the factories because they could be manufactured more cheaply.Industry 3.0

Automation, computers and electronics

Der Übergang zur nächsten industriellen Revolution wurde durch die Entwicklung von Computern ermöglicht. Seit Elektronik-Komponenten in den 70er Jahren für den Einsatz in industriellen Umgebungen bereit waren, wurde in der Produktion die Automatisierung mit Elektronik, IT und Speicher programmierbaren Steuerungen (SPS) vorangetrieben. Maschinelle Abläufe und Regelungen konnten hoch effizient gesteuert werden und menschliche Eingriffe auf ein Minimum reduziert werden. Dies ist die revolutionäre Entwicklung gegenüber der Reihenfertigung, in der die Maschinen nur wenig autark arbeiten konnten. Die Entwicklung der Elektronik ging rasant voran, so dass Steuerungen immer leistungsfähiger und kleiner wurden. Immer mehr Geräte konnten mit eigener Intelligenz ausgestattet werden. In dem Zuge waren auch immer mehr Daten verfügbar, die aus der automation could be recorded. In Industry 3.0, however, evaluations of this data can only ever be carried out in retrospect and the findings can only be slowly fed back into automation.Industry 4.0

Digitalisation, networks and the Internet of Things (IoT)

The fourth industrial revolution entwickelt sich jetzt, indem die intelligenten Automatisierungsgeräte und alle anderen an der Produktion beteiligten Systeme bestmöglich vernetzt werden. Durch die Vernetzung entstehen revolutionäre Möglichkeiten in der Abstimmung der Systeme untereinander. Jedes System kann jederzeit an die Informationen gelangen, die es für einen optimalen Betrieb benötigt und ebenfalls kann es seine eigenen Daten zur Verfügung stellen. Dadurch entsteht in der Industry 4.0 die Möglichkeit der Selbstoptimierung und Selbststeuerung und damit die intelligente Fabrik. Die Vernetzung ist nicht auf bestimmte Bereiche begrenzt und schließt auch die produzierte Ware selbst mit ein. Daten aus dem Lebenszyklus des Produktes fließen in die Entwicklung zurück und können direkten Einfluss auf die aktuelle Produktion nehmen. Maschinen können Ihren Zustand mit anderen Produktionssystemen teilen, die wiederum darauf reagieren können. In der Industry 4.0 the customer is also integrated in the best possible way, so that customer wishes are optimally incorporated into production, right up to production with batch size 1 (see Industry 4.0 goals).The transformation to Industry 4.0 creates efficiency, flexibility and many opportunities for further development and thus competitive advantages and improvements in working conditions and environmental compatibility.As with the other industrial revolutions, the changeover is not sudden, but steady and unstoppable.

More information

What is OPC UA?

OPC Unified Architecture (UA) is the foundation for the emerging Internet of Things (IoT). Read in our article "What is OPC UA?", what OPC UA means for companies and how you can use OPC UA to strengthen your company's competitiveness.

The 5 key factors for successfully connecting machines

Für eine erfolgreiche Maschinenanbindung sollten einige grundlegende Voraussetzungen berücksichtigt werden. Wir gehen in unserem Beitrag “The 5 key factors for successfully connecting machines” unter anderem auf die Aspekte Netzwerkanbindung, Kommunikationsprotokolle und OPC UA sowie auf die Anforderungen an die Maschinendaten ein.

Practical implementation of Industry 4.0

Our products are designed to collect data, merge it and make it available at the right time and in the right place. With OPC Router, the OPC UA Server KEPServerEX and the Factory Application Server FAS you can easily integrate Industry 4.0 in your company.